Case study: Rapid prototyping for faster and more cost efficient nuclear decommissioning

To support nuclear waste material retrievals at Sellafield’s Magnox Swarf Storage Silo in January 2024, the onsite Retrievals, Innovation and Optimisation Technology (RIOT) team worked with Actemium and Fortis to create and deploy a custom sonar system that safely inspected waste compartments in low-oxygen conditions.

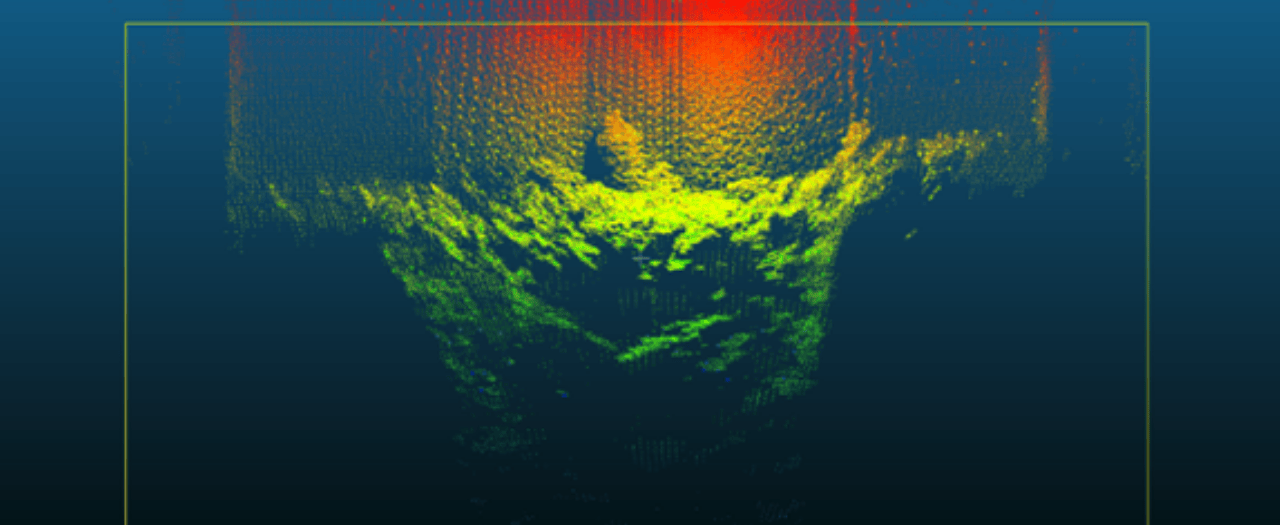

Screen grab of silo floor visualised by sonar solution

Project Overview

- Sector: Nuclear Decommissioning

- Location: Sellafield, Cumbria

- Actemium BU: Actemium Design UK in partnership with Fortis Remote Technology Solutions

- Expertise: Mechanical Engineering, Rapid Prototyping, 3D Printing

- Scope: Design, Modify, Trial & Deploy

- Solution: Custom sonar deployment method using modified equipment and cable-marking system

Our Client & Their Requirements

Sellafield, located on the coast of Cumbria, England, is one of the UK’s largest and most complex nuclear sites, focused on the safe processing, storage, and decommissioning of nuclear waste. Within the site, the RIOT (Retrievals, Innovation and Optimisation Technology) team leads the development of innovative technical solutions to support safe and efficient waste retrieval and inspection.

As part of the Magnox Swarf Storage Silo (MSSS) retrievals in January 2024, the RIOT team was tasked with inspecting the waste profile inside a submerged compartment. Since 2022, waste has been retrieved using a sophisticated machine that reaches underwater to collect material. However, limited visibility made it difficult to determine where raking was needed before waste could be safely grabbed.

The Challenge

Because the compartment was under inerted conditions – a low-oxygen environment designed to prevent combustion – traditional video inspection was not possible. The RIOT team had been exploring the use of Remotely Operated Vehicles (ROVs) to inspect the waste profile for two years already and now needed a more reliable and safe method to deploy sonar equipment remotely, enabling accurate data collection while minimising the risk of contamination.

They were seeking experienced partners to design a suitable deployment method and modifying existing equipment to suit the silo conditions.

The project presented several technical and operational challenges:

- Designing a deployment method suitable for the above environment

- Modifying existing equipment for sonar integration.

- Developing a cable-marking system to track sonar depth and position during blind deployment.

- Ensuring containment integrity and preventing contact with waste.

- Validating the method through offsite trials and training.

The Solution

The RIOT team engaged Fortis Remote Technology Solutions (sonar supplier) to select sonar equipment and adapt the deployment setup accordingly.

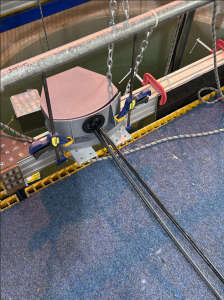

Working alongside Fortis, Actemium Design UK produced and organised off-site trials using a 3D-printed replica of the deployment equipment to validate the sonar method and train the team in its operation. Actemium also supported the Plant Modification Proposal (PMP) process, maintained close engagement with the plant throughout, and operated the sonar system during deployment—ensuring successful data collection and system performance.

Trial images

After deployment, Fortis processed the sonar data, while Actemium Design UK aligned it with the compartment’s geometry using AODs. Actemium was then tasked with estimating the volume of waste removed to help assess skip fill efficiency. A second sonar deployment is planned following raking operations to further support waste retrieval.

Key features of the final solution included:

- A modified system tailored for sonar deployment.

- An operationally proven cable-marking method to ensure accurate scan overlay.

- A locking and clamping system to prevent cable movement and maintain containment.

- Offsite trials to ensure operational readiness and safety.

- Onsite deployment and operation by Actemium, with successful data collection.

Client Benefits

The delivered sonar deployment solution provided RIOT and the MSSS project team with significant operational efficiency and cost advantages – i.e.:

- Improved mapping of the waste profile in the silo, allowing for better and quicker decision making when and where waste needs to be raked

- Two to four years faster retrieval timeline

- A reduction in the number of rakes used, resulting in £240 – £550 million saving

- Improved skip fill efficiency estimation through post-deployment analysis.

- An established a foundation for future reusable sonar deployments.

Next Steps

Following the successful initial deployment, RIOT has been tasked with:

- Developing a reusable sonar deployment method to avoid equipment loss.

- Investigating sonar use to identify blocked interconnecting ducts between compartments.

Actemium has confirmed sonar viability for duct inspection, pending confirmation of a reusable deployment method.

Have a nuclear project we can support? Get in touch with our team at reachout@actemium.co.uk